1. TERMS OF USE:

Registration at PICSCI is contingent upon your accepting this Agreement. Acceptance of this Agreement and all of its terms and conditions allows access to and use of The PICSCI Electronic Lab Notebooks System, hereafter referred to as PICSCI. By selecting the "Accept" checkbox, you accept all the terms and conditions of this binding Agreement between site user (you), and Matereality, LLC, including, but not limited to, the warranty, disclaimer, limitation of liability, and termination provisions below. All registered users should consult this page for conformance with terms of use before access and use of PICSCI. Access to and use of PICSCI is permitted only by authorized users. Any other access or use is strictly prohibited. By registering, you certify that all information that you have provided as part of your registration is complete, accurate and correct.

2. MODIFICATIONS:

Matereality, LLC reserves the right to make modifications to PICSCI from time to time without obligation to notify you, or any other person or organization of such revision or change. All registered users should consult this page for conformance with terms of use before each access and use of PICSCI.

3. LIMITED ACCESS AND USE PRIVILEGE:

Subject to the terms and conditions of this Agreement, Matereality, LLC hereby grants you a personal, limited, revocable, nonexclusive, nontransferable, nonsublicensable license to access PICSCI from any computer under your control at any time. The content at this site has been provided to you by other users, through PICSCI. Matereality, LLC does not accept any obligation or liability for consequences resulting from use of this content.

You acknowledge that the design and structure of PICSCI is owned by Matereality, LLC and protected by US Patents 7,613,700 and 7,873,667. You agree to retain and abide by all patent, copyright, and related notices of Matereality, LLC included with, and on the PICSCI web site, its printed reports, downloadable documents, and any related materials. You may not: (a) modify, translate, or reproduce the PICSCI data structure or delete or alter any content posted by any other party; (b) sell or redistribute PICSCI content that you do not own; (c) collect, organize, or catalog the PICSCI information outside PICSCI; (d) sublicense, rent, lend, transfer, post, transmit, or otherwise make the PICSCI content available to anyone else; (e) make your password and login information available to anyone else, including posting your password in electronic format on web sites, news groups, or other public-access forums; (f) export PICSCI content, except as permitted; (g) use PICSCI in any manner which is defamatory, pornographic, obscene, abusive, libelous, threatening, harassing, fraudulent, or otherwise violates any applicable laws; (h) use any device, software or routine to interfere, or attempt to interfere, with the proper operation of PICSCI. You agree to be solely responsible and liable for any illegal act, unlawful act, intentional act, negligence, gross negligence, or breach of this Agreement by you (or any party acting on your behalf) in conjunction with the use of PICSCI.

4. ACKNOWLEDGEMENT OF TRADEMARKS, COPYRIGHTS:

You acknowledge that PICSCI, related logos, and designs are trademarks of Matereality, LLC and that no rights in such trademarks are granted to you by this Agreement. All software enabling access and functionality of PICSCI are copyrights of Matereality, LLC.

5. PRIVACY/NATURE OF BUSINESS:

PICSCI has been designed to facilitate database creation, data information exchange, between data owners and data users. This easy access to information must be protected through secure mechanisms that allow safeguards of the data owner's interests. Owners of data should know that while every reasonable technical, administrative, and physical step to ensure confidentiality of data will be taken to ensure the security of PICSCI, Matereality, LLC will not be held liable for theft of information by third parties using illegal means. Matereality, LLC will be vigilant against any threats to security and will execute all legal powers to defend it. Matereality, LLC will not reveal personal information collected from you to unrelated third parties.

6. NO WARRANTIES:

PICSCI presents to you the infrastructure and means for exchange of data. PICSCI, LLC gives no assurances and makes no representations with respect to such information. In no event shall the availability of such information be considered as any indication that it has been validated in any way by Matereality, LLC. You acknowledge that Matereality, LLC is not in the business of rendering engineering or structural advice. PICSCI provides a platform for sharing and distributing materials properties information, which may be used in structural or engineering decisions, at your own risk. Matereality, LLC shall not be held responsible or liable for the accuracy or inaccuracy of the information it allows to be stored, organized, and accessed through its site. Accordingly, if you rely on PICSCI in making structural or engineering decisions and calculations, you do so at your own risk, and you should verify any and all data utilized and calculations you make through the relevant data owner, or through independent testing.

7. DATA QUALITY & LIMITATION OF LIABILITY:

We have reviews at the point of collection, as well as at the end of data analysis processes. IN NO EVENT WILL MATEREALITY, LLC, ITS ASSOCIATES, SUPPLIERS, OR OTHER THIRD PARTY PARTNERS, BE LIABLE FOR ANY DAMAGES, INCLUDING LOSS OF DATA, LOST OPPORTUNITY OR PROFITS, BUSINESS INTERRUPTION, COST OF COVER OR ANY SPECIAL, INCIDENTAL, CONSEQUENTIAL, DIRECT OR INDIRECT DAMAGES ARISING FROM OR RELATING TO THE USE OF MATEREALITY AND ITS CONTENT, HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER OR NOT MATEREALITY, LLC HAS BEEN ADVISED OR GIVEN NOTICE OF THE POSSIBILITY OF SUCH DAMAGE. THE ENTIRE RISK AS TO THE USE OF MATEREALITY IS ASSUMED BY THE USER.

8. DISCLAIMER:

TO THE FULLEST EXTENT PERMITTED BY APPLICABLE LAW, PICSCI AND ITS CONTENT, INCLUDING BUT NOT LIMITED TO ALL DATA, TOOLS AND CALCULATIONS THEREIN ARE PROVIDED "AS IS" AND WITHOUT EXPRESS OR IMPLIED WARRANTY OF ANY KIND, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF TITLE, MERCHANTABILITY, OR FITNESS FOR A PARTICULAR USE, BY EITHER MATEREALITY, LLC OR ANYONE ELSE WHO HAS BEEN INVOLVED IN THE CREATION, PRODUCTION OR DELIVERY OF PICSCI. NO COVENANTS, WARRANTIES OR INDEMNITIES OF ANY KIND ARE GRANTED BY MATEREALITY, LLC TO YOU THE USER.

9. TERMINATION CLAUSE:

If you do not accept the terms of this Agreement, you agree to stop the registration process for access and use of PICSCI. This Agreement and your rights under this Agreement shall automatically terminate upon any failure by you to comply with its terms and conditions. In addition thereto, Matereality, LLC reserves the right to deactivate or suspend use of PICSCI at any time and for any reason.

10. GOVERNING LAWS:

This Agreement will be governed by the laws of the State of New York, USA, excluding the application of its conflicts of law rules.

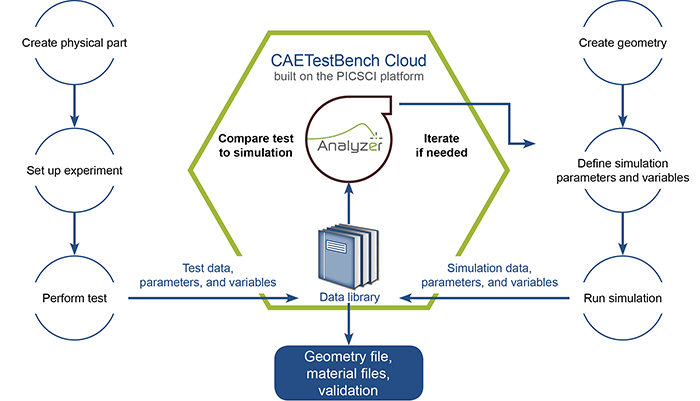

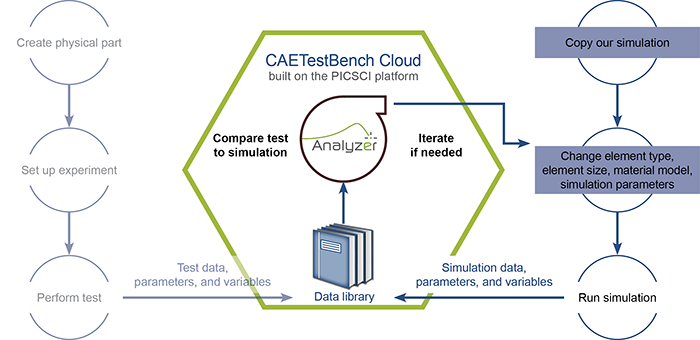

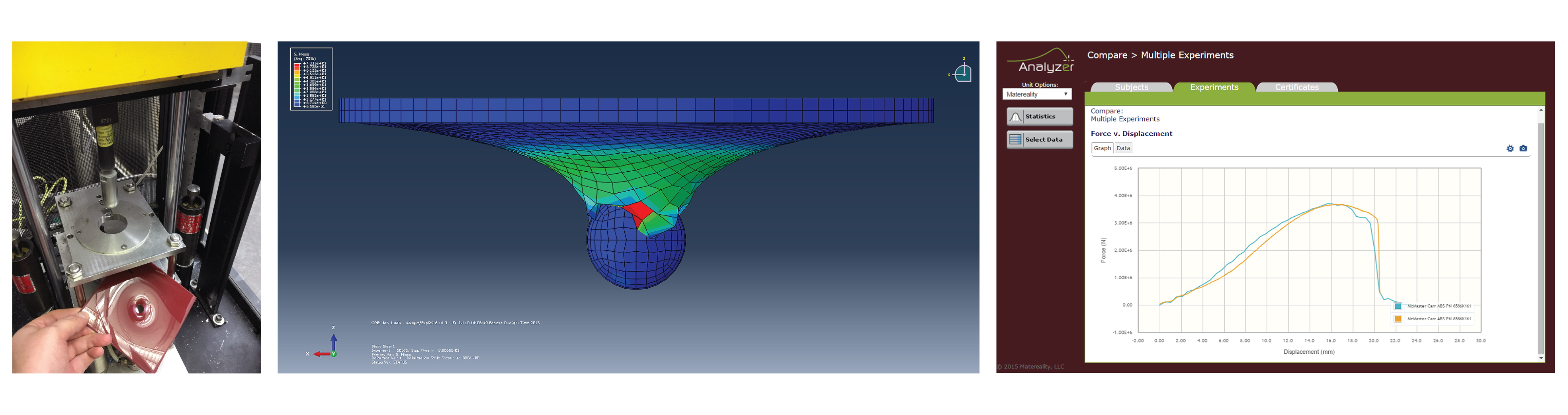

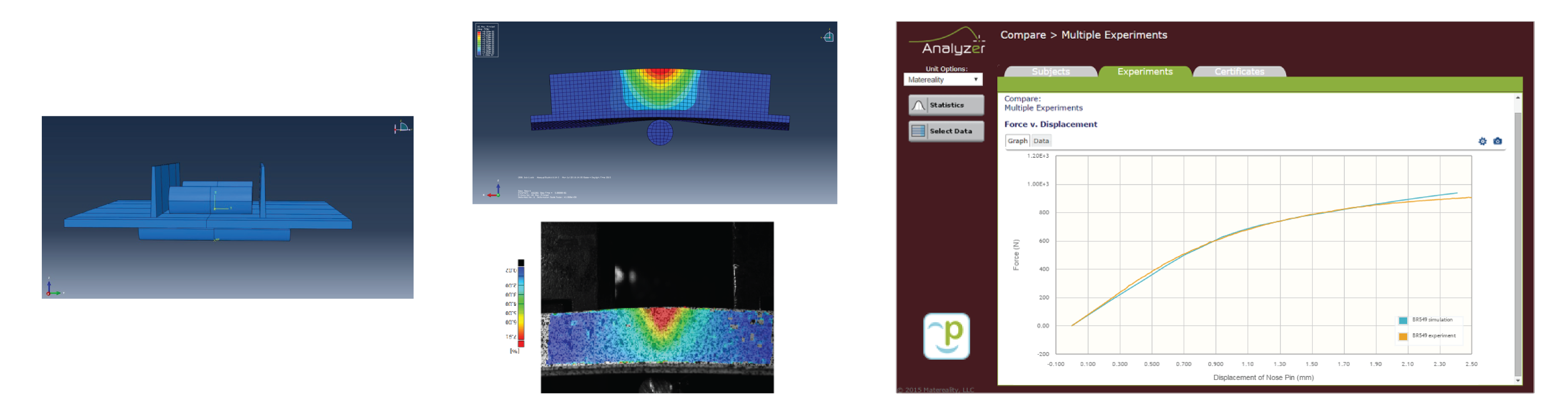

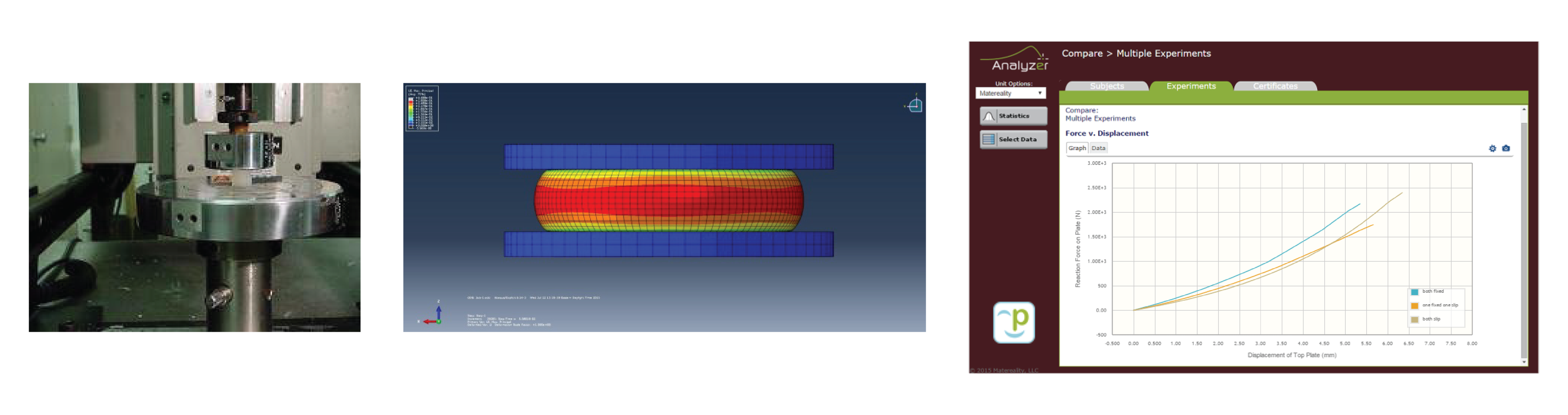

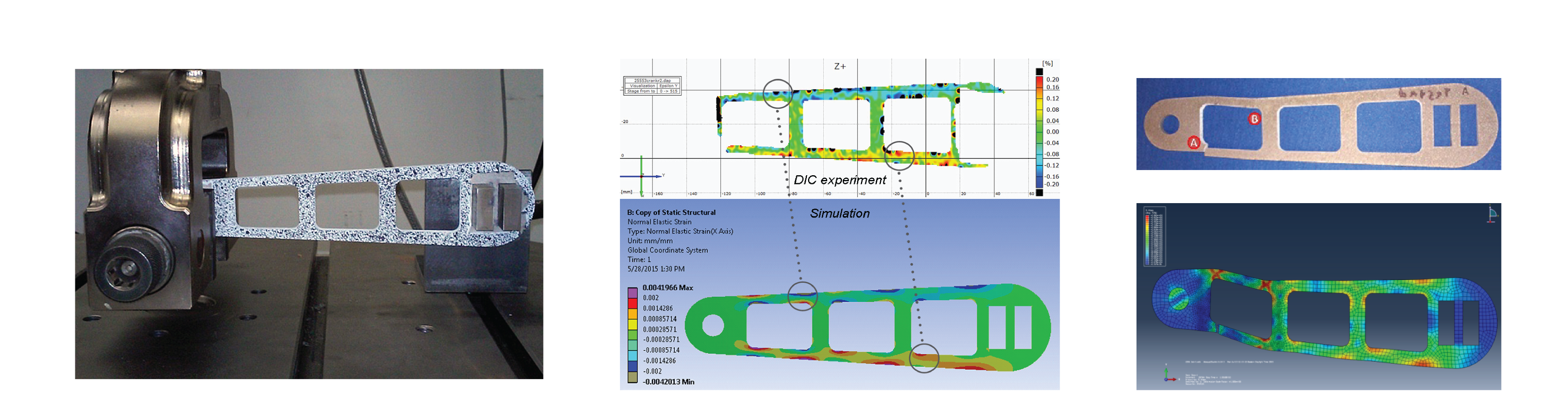

Validation of Simulation

Validation of Simulation